Stalco Perfect Chemical Anchors – Types, Mechanism, and Applications

In the construction industry, anchorages are divided into two types: mechanical anchorages and chemical anchorages. Mechanical anchorages, such as expansion anchors, are easy and convenient to use for low and medium-strength fixings. For permanent and high-strength or critical conditions, resin anchoring is more balanced and more frequently used.

What is a Chemical Anchor?

Chemical anchors refer to rebars or threaded rods that are bonded into a substrate, usually masonry or concrete, using a resin-based adhesive system. These anchors create very strong bonds, often stronger than the base material itself. Chemical anchors are ideal if you are unsure about the building material or the quality of the concrete you are using.

Types of Chemical Anchors

The specific type of chemical anchor depends on the substrate, strength requirements, and curing requirements.

Polyester Styrene-Free Chemical Anchor

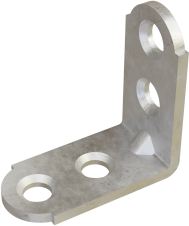

This type of anchor is used for professional fastening systems for medium and high loads. It can be used for certified fastening of wooden and steel structures, gates, railings, balustrades, trays, brackets, cable tunnels, satellite antennas, canopies, awnings, etc., in lightweight concrete with high porosity, hollow blocks, aerated concrete, solid lightweight concrete brick, silicate brick, and solid brick.

Application:

- Two-component polyester mortar with universal application.

- Styrene-free, ideal for poorly ventilated spaces as it does not emit an unpleasant odor.

- Can be used on wet and damp substrates.

- Non-reactive with water and chemicals.

- Resistant to external factors and aging.

- Does not introduce initial stresses to the substrate.

- Fast setting time - as little as 30 minutes.

- No cracking or expansion effect, allowing for close-to-edge installation.

- Open cartridges can be reused by replacing the mixing nozzle.

- Can be applied with standard silicone guns.

Vinyl Styrene-Free Chemical Anchor

This high-strength chemical anchor is used for anchoring rebars and threaded rods in masonry and concrete under medium loads. It exhibits high strength and chemical resistance, making it suitable for use in low-integrity concrete. It can be used in both dry and damp concrete.

Application:

- Anchoring elements such as rebars and threaded rods in concrete, reinforced concrete, cracked concrete, and natural stone.

- Securing structural steel elements to protective barriers, bases, device and machine pedestals, guides, rails, grates, wooden structures, window frames, connectors, and cable conduits.

- Securing multi-layered arches, suspended and lighting installations, multi-layer wall connections.

- Repairing bay windows, cornices, and lintels.

Epoxy Chemical Anchor

Epoxy chemical anchors are designed for the highest loads. They are used primarily in solid materials and can be used underwater and in wet substrates but not at sub-zero temperatures. This type of chemical anchor has a long curing time - up to several hours.

Application:

- Anchoring in water-filled holes made with diamond techniques.

- Anchoring heavy equipment and machines.

- Securing dock infrastructure.

- Anchoring heavy steel structures, silos, load-bearing columns.

- Securing connectors for overlaid concrete layers.

- Anchoring dock infrastructure.

Chemical Anchor Accessories

Stalco Perfect stands out from the competition by offering a full range of accessories required for these types of jobs, whereas competitors often only offer the anchors themselves.

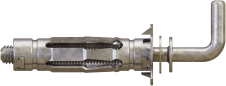

X9S Mixing Nozzle

The X9S mixing nozzle for two-component composite masses ensures even mixing of composite mortars, resulting in optimal mass quality. Its modern mixing spiral with a diffuser significantly reduces the compression force compared to standard mixers.

X9S Mixing Nozzle Extension

The X9S mixing nozzle extension is a complementary element of the chemical anchoring system, facilitating the application of resins in hard-to-reach and deep holes.

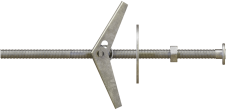

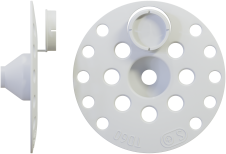

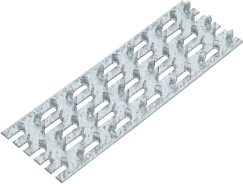

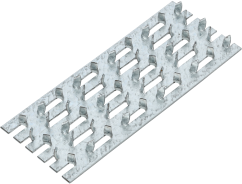

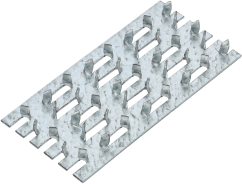

Nylon Mesh Sleeves

Mesh sleeves, often called anchor sleeves, are practical accessories used when processing composite mortar in combination with perforated bricks and hollow blocks. Their benefits include:

- No need to clean and blow out holes.

- Suitable for use in substrates with hollow blocks.

- A centering plug that maintains the anchor rod axially and prevents mortar from flowing out of the sleeve.

- Ensures even distribution of resin in holes and reduces resin consumption.

Conclusion

Chemical anchors provide strong and reliable fixings in various construction applications, especially where high strength and durability are required. By choosing the right type of chemical anchor and using the appropriate accessories, you can ensure safe and efficient anchoring solutions for your projects. Stalco Perfect offers a comprehensive range of chemical anchors and accessories to meet diverse construction needs, ensuring quality and performance in every application.